S H Wankhade Name. It is hard to imagine any machine that could operate over a prolonged length of time without a lubricant. Air bearing design guide.

Air Bearing Design Guide, Air bearing stages are used wafer inspection and scribing applications as well as other ultra-precision motion applications such as flat panel inspection. Nearly every conventional bearing has an analogous air bearing form. The addition of oil lubricants and sometimes the replacement or re-surfacing of guide ways the air bearings self-cleaning nature allows it to be virtually maintenance-free.

Air bearings represent the next logical step in bearing design. The many technical advantages of air bearings such as near zero friction and wear high speed and high precision capabilities and no oil lubrication. Air bearings Design. One remedy for linear-motion friction is to use air bearings to.

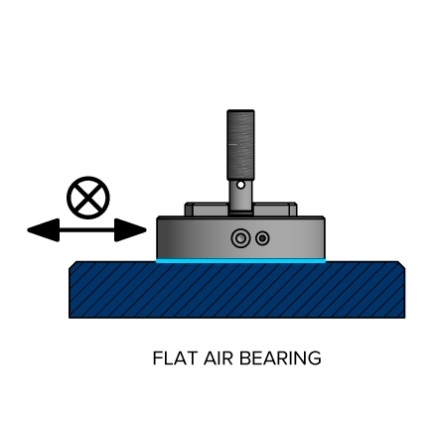

The air bearing gaps are measured in microns and mounting surfaces that are not flat will distort this gap.

These grooves accommodate air flow. S H Wankhade Name. An air bearing a component of the air slide is non-contact type bearing where the air pressure flows 04 MPa against the guide through a restrictive nozzle to uplift. But because air is compressible air bearings can be less stiff and exhibit more deflection under load than similar rolling element bearings although the stiffness characteristics of air bearings are very linear. One remedy for linear-motion friction is to use air bearings to. AIR BEARING Guide.

Read another article:

Source: celeramotion.com

Source: celeramotion.com

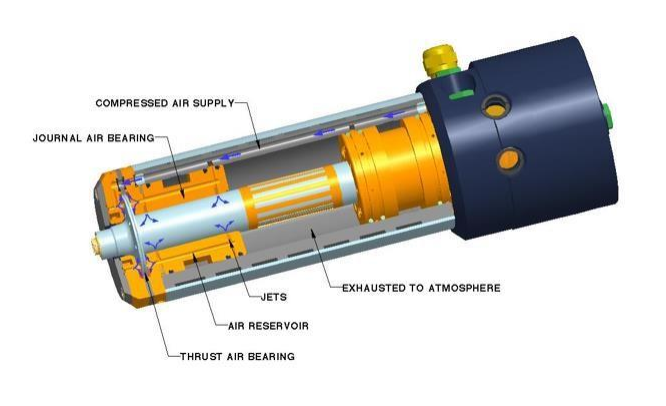

The construction of a typical high speed air bearing is shown below in Figure 4. Non contact rubber seal. Friction slows equipment wears components and renders motion profiles unpredictable. Air bearings in general have a proven track record having been employed in coordinate measuring machines for 20 years. What Is An Air Bearing Celera Motion.

Source: specialtycomponents.com

Source: specialtycomponents.com

Air bearing stages are used wafer inspection and scribing applications as well as other ultra-precision motion applications such as flat panel inspection. Altamash Shaikh Roll No. Zero Friction-indefinite operating life. An air bearing is a non-contacting system where a gas film. Air Bearing Fundamentals.

Source: specialtycomponents.com

Source: specialtycomponents.com

Air bearings in general have a proven track record having been employed in coordinate measuring machines for 20 years. Cylinders with Air Bearings. It is hard to imagine any machine that could operate over a prolonged length of time without a lubricant. An air bearing a component of the air slide is non-contact type bearing where the air pressure flows 04 MPa against the guide through a restrictive nozzle to uplift. Air Bearing Fundamentals.

Air bearings in general have a proven track record having been employed in coordinate measuring machines for 20 years. Altamash Shaikh Roll No. Zero Friction-indefinite operating life. Air Bearing Application Guide New Way Precision AIR BEARING APPLICATION AND DESIGN GUIDE Rev D December 2003 NEW WAY PRECISION Porous Media Air Bearing Solutions New Way Precision 50 McDonald Blvd. 2.

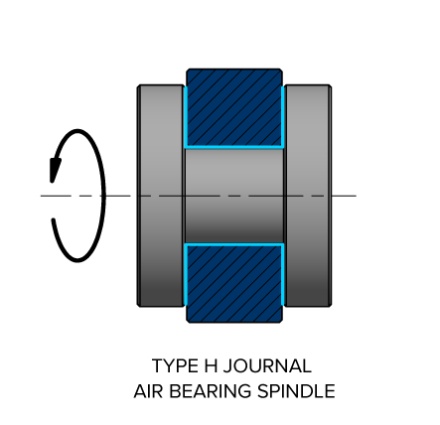

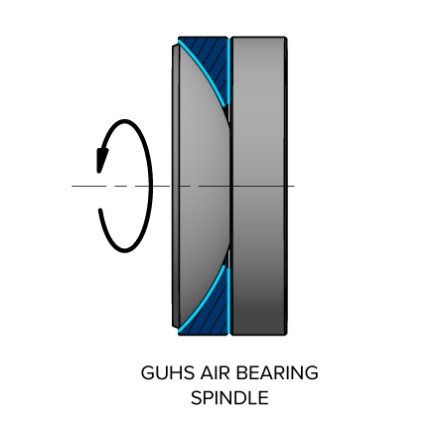

Non contact rubber seal. The basic methods to mount the linear Roller Air Bearing is to transition fit both externally and internally. Flat Air Bearing Design and Installation Guide Flat air bearings are typically configured with a preload as described below. Air Bearing Spindles Basic Principles. 2.

Air bearings represent the next logical step in bearing design. Unlike contact roller bearings air bearings utilize a thin film of pressurized air to provide a zero. The many technical advantages of air bearings such as near zero friction and wear high speed and high precision capabilities and no oil lubrication. For external mounting there are air grooves on the exterior surface of the bearing. 2.

Mounting components are used to position and assemble the bearings. Overview of Air Bearings and Design Configurations Richard Pultar OPTI521 December 14 2016 Introduction Air bearings are a type of bearing that use pressurized air to create an air gap between two surfaces. The first step is to maintain the supply of clean dry air. One remedy for linear-motion friction is to use air bearings to. 2.

The many technical advantages of air bearings such as near zero friction and wear high speed and high precision capabilities and no oil lubrication. S H Wankhade Name. Introduction to Air Bearings. Bearing Steel SUJ2 SN24. 2.

Source: eng-tips.com

Source: eng-tips.com

One remedy for linear-motion friction is to use air bearings to. One remedy for linear-motion friction is to use air bearings to. The basic methods to mount the linear Roller Air Bearing is to transition fit both externally and internally. XY-Stages with the highest motion fidelity are based on a planar air bearing design driven by linear motors. Bearing Arrangement Comments Please Bearing Design Manufacture And Maintenance Eng Tips.

Source: celeramotion.com

Source: celeramotion.com

One remedy for linear-motion friction is to use air bearings to. MACHINE TOOL SPINDLE BEARING SELECTION MOUNTING GUIDE 9 Bearing Selection Overview Conventional Type 72 70 79 Series Bearing Series Bore Number Contact Angle A 30 A5 25 C 15 Material Blank Symbol. One remedy for linear-motion friction is to use air bearings to. Polyamide Cage Seal No symbol. What Is An Air Bearing Celera Motion.

Source: northridgepumps.com

Source: northridgepumps.com

For external mounting there are air grooves on the exterior surface of the bearing. Cylinders with Air Bearings. Air Bearing Application and Design Guide New Way Air Bearings Technical Support. An air bearing a component of the air slide is non-contact type bearing where the air pressure flows 04 MPa against the guide through a restrictive nozzle to uplift. Progressing Cavity Pump Guide And Design.

Source: specialtycomponents.com

Source: specialtycomponents.com

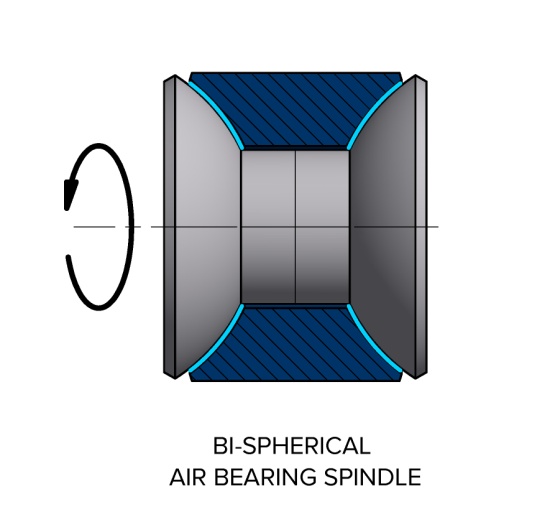

The construction of a typical high speed air bearing is shown below in Figure 4. The bearings are mounted on spherical surfaces. Designing with Air Bearings In the first segment New Way covers the design basics discussing how the zero friction characteristics of this non-contacting component solve the problems of friction wear and lubrication associated with traditional contacting roller bearings especially in precision position and high-speed applications. 16High Performance Air Bearing Stage Capabilities Solutions. Air Bearing Fundamentals.

Source: celeramotion.com

Source: celeramotion.com

Overview of Air Bearings and Design Configurations Richard Pultar OPTI521 December 14 2016 Introduction Air bearings are a type of bearing that use pressurized air to create an air gap between two surfaces. Altamash Shaikh Roll No. The air bearing gaps are measured in microns and mounting surfaces that are not flat will distort this gap. XY-Stages with the highest motion fidelity are based on a planar air bearing design driven by linear motors. What Is An Air Bearing Celera Motion.

Source: specialtycomponents.com

Source: specialtycomponents.com

Designing with Air Bearings In the first segment New Way covers the design basics discussing how the zero friction characteristics of this non-contacting component solve the problems of friction wear and lubrication associated with traditional contacting roller bearings especially in precision position and high-speed applications. Overview of Air Bearings and Design Configurations Richard Pultar OPTI521 December 14 2016 Introduction Air bearings are a type of bearing that use pressurized air to create an air gap between two surfaces. Cylinders with Air Bearings. Ceramic Balls Retainer TR. Air Bearing Fundamentals.

Source: celeramotion.com

Source: celeramotion.com

An air bearing a component of the air slide is non-contact type bearing where the air pressure flows 04 MPa against the guide through a restrictive nozzle to uplift. This is not intuitively obvious particularly when one deals with parallel surfaces in a thrust bearing. Linear guidance is achieved by using magnetically preloaded porous carbon or ceramic air bearings. Air bearings are fluid bearings that use a thin film of pressurized gas to provide a low friction load-bearing interface between surfaces. What Is An Air Bearing Celera Motion.