Cross-section Select a Quad-Ring Brand cross-section size from the available standard sizes. Once you find the right o-ring groove design you can easily order online from the worlds largest o-ring inventory network. Apple rubber o ring groove design.

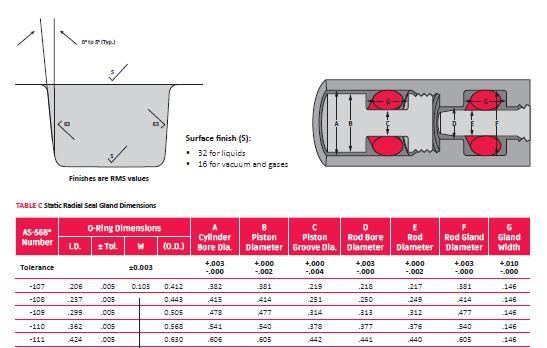

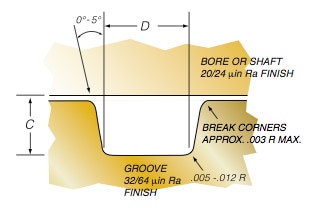

Apple Rubber O Ring Groove Design, Basic Application Groove Design Reference Charts - Expert Application Engineer Support. The second tradeoff is that 90 durometer rings are less tolerant of a poor finish so you need to maintain the prescribed 16 rms finish on the bore and groove OD. Groove Bore Piston Rod Figure 1-2.

- Before installation and where applicable make sure to lightly coat the O-ring with a compatible lubricant. Choose whether you are working with existing hardware or designing new hardware. Dynamic Reciprocating O-Ring Gland Design. 30 per line item minimum.

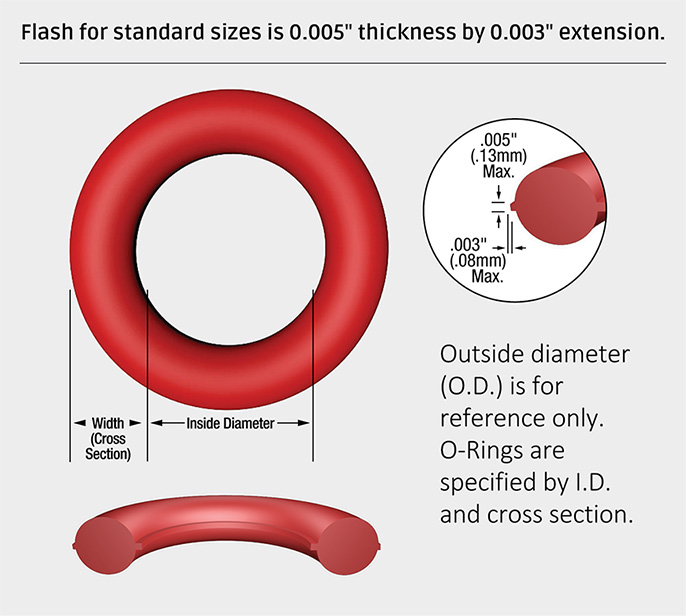

In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways.

The second tradeoff is that 90 durometer rings are less tolerant of a poor finish so you need to maintain the prescribed 16 rms finish on the bore and groove OD. This is the first number that is needed. Make sure that the material you choose will withstand the temperature of your system by. In reciprocating sealing applications there is a back and forth or reciprocating motion along the shaft axis between the inner and outer parts of the gland. Basic Application Groove Design Reference Charts - Expert Application Engineer Support. Be it dynamic or static operation radial or axial loading vacuum or high pressure.

Read another article:

Source: vizeng.com

Source: vizeng.com

O-ring Groove Design in 3 easy steps. If the O-ring size required is known simply select the AS BS or ISO standard such as. The new Inspection Specifications addition to the Seal Design Guide includes information on. If you have a custom O-ring size that does not appear on this chart contact us directly and we can help you size your O-ring gland design accordingly. How To Design An O Ring Groove Vizeng.

Source: globaloring.com

Source: globaloring.com

O-ring groove design is a key consideration in the o-ring selection process. - Before installation and where applicable make sure to lightly coat the O-ring with a compatible lubricant. Basic Application Groove Design Reference Charts - Expert Application Engineer Support. 30 per line item minimum. Bs 4518 Metric O Rings Global O Ring And Seal.

Source: pinterest.com

Source: pinterest.com

Standard-sized O-rings are readily available in the following materials. Choose whether you are working with existing hardware or designing new hardware. Try our new Online O-ring Store. In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways. Protect Your Ipad 9 7 Model By Utilizing This Protective Rugged Case With Rubber Bumpers Comes With Handstrap Br Water Proof Case Ipad Case Ipad Accessories.

Source: applerubber.com

Source: applerubber.com

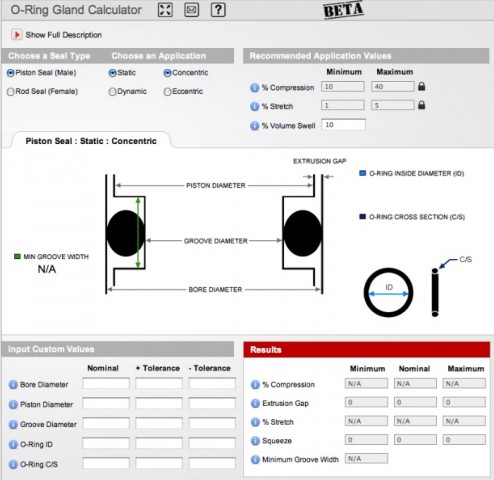

Standard-sized O-rings are readily available in the following materials. The best o-rings are useless without the right groove design which becomes increasingly important the more demanding the application environment. O-ring groove design guides offer default dimensional guidance on the most basic o-ring groove design applications. Expert Application Engineering Assistance. New Gland Calculator Tool At Applerubber Com Official Apple Rubber Blog.

Source: studylib.net

Source: studylib.net

Having a circular cross section that functions as a seal in both static and dynamic applications by being compressed between the mating surfaces comprising the walls of the gland in which it is installed. Backup rings are likely needed. Groove Bore Piston Rod Figure 1-2. Be it dynamic or static operation radial or axial loading vacuum or high pressure. O Ring Basics Apple Rubber.

Source: applerubber.com

Source: applerubber.com

Expert Application Engineering Assistance. The O-ring Figures 1-2 and 1-3. O-ring and gland constitute the classic O-ring seal assembly. Grooves for PTFE O-Rings are similar to those for rubber O-Rings except that less squeeze is applied due to the relative stiffness of the material. O Rings Standard As568 Iso 3601 Apple Rubber Products.

Source: pinterest.com

Source: pinterest.com

Based on the cross section CS of your O-ring you will choose the corresponding O-ring groove depth and O-ring groove width dimensions. Also the groove width is generally less as PTFE O-rings are much less likely to roll in reciprocating applications than their elastomeric counterparts. If the O-ring size required is known simply select the AS BS or ISO standard such as. On the flip side an External Groove aka a male gland the design will be based on the minimum bore diameter that the o-ring will seal against. 1pcs 6016 2rs 6016 Rs 80x125x22mm Rubber Sealed Deep Groove Ball Bearing Brand New Deep Rings For Men Groove.

Source: pinterest.com

Source: pinterest.com

O-ring Groove Design in 3 easy steps. The combination of these two elements. Choose whether you are working with existing hardware or designing new hardware. The O-ring Figures 1-2 and 1-3. Pin On Smartwatch Bands.

Source: applerubber.com

Source: applerubber.com

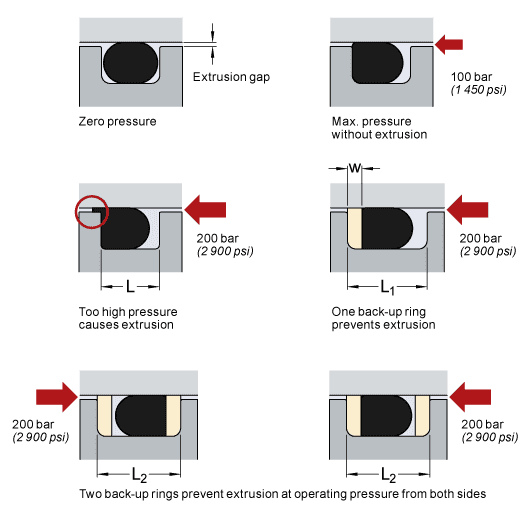

In the long stroke of a reciprocating seal application this twisting action can strain and eventually tear the rubber causing a failure mode known as spiral twist. Male or Plug - the O-ring groove is located on a plug which is inserted into the housing or cylinder fig. Backup rings are likely needed. If the O-ring size required is known simply select the AS BS or ISO standard such as. How To Save Time On Medical Rubber Part Design Hot Topics.

Source: applerubber.com

Source: applerubber.com

The combination of these two elements. The groove shape is very similar to that of face seals. Now follow the steps below to design your own o-ring seal and o-ring groove. Also the groove width is generally less as PTFE O-rings are much less likely to roll in reciprocating applications than their elastomeric counterparts. 4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics.

Source: mnrubber.com

Source: mnrubber.com

The O-ring Figures 1-2 and 1-3. Now follow the steps below to design your own o-ring seal and o-ring groove. - When using only one back-up ring be sure to install it on the low-pressure side of the O-ring. Be it dynamic or static operation radial or axial loading vacuum or high pressure. Groove Design O Ring Seals Minnesota Rubber Plastics.

Source: skf.com

Source: skf.com

Grooves for PTFE O-Rings are similar to those for rubber O-Rings except that less squeeze is applied due to the relative stiffness of the material. You will find in-depth information on each of these rules and more in the new Seal Design Guide published by Apple Rubber Products. Oring Groove Design As important as the oring seal itself is the groove that the oring seats into. The groove walls dont matter. O Rings And Back Up Rings Skf Skf.

Source: mnrubber.com

Source: mnrubber.com

Groove Bore Piston Rod Figure 1-2. O-ring and gland constitute the classic O-ring seal assembly. Once you find the right o-ring groove design you can easily order online from the worlds largest o-ring inventory network. If you are unsure what cross-section size to use see here. Groove Design O Ring Seals Minnesota Rubber Plastics.

Source: es.pinterest.com

Source: es.pinterest.com

This is the first number that is needed. O-ring and gland constitute the classic O-ring seal assembly. Standard-sized O-rings are readily available in the following materials. The second number that is required is the O-ring Series that you. Montre F1 Carbon Gmt Concept Watch Cool Watches Watch Design Watches For Men.

Source: mnrubber.com

Source: mnrubber.com

In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways. This is the first number that is needed. In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways. Male or Plug - the O-ring groove is located on a plug which is inserted into the housing or cylinder fig. Groove Design O Ring Seals Minnesota Rubber Plastics.