It is a sharp delineation between covered and exposed wood. In fact most pre-finished hardwood is made using this technology. Hardwood floor finish uv protection.

Hardwood Floor Finish Uv Protection, All wood reacts to sunlight. UV finishes are low in volatile organic compounds or low-VOC. Unfortunately too the wood under the varnish eventually begins to deteriorate so that the adhesion between varnish and wood is reduced and you begin to see yellow patches that means it is time to strip it all off and start over.

Pin On Texture Background From pinterest.com

Pin On Texture Background From pinterest.com

Although polyurethane finishes remain popular UV oiled finishes provide a variety of benefits that attract discerning homeowners. KEY BENEFITS Appeals to consumers who select a wood floor based on its colour Useful for architects specifying wooden floors as part of an interior scheme Lengthens the time a natural wood floor keeps its original colour Can be used for all kinds of wood. The Benefits of UV Hardwood Floor Coatings. Unfortunately too the wood under the varnish eventually begins to deteriorate so that the adhesion between varnish and wood is reduced and you begin to see yellow patches that means it is time to strip it all off and start over.

In my experience there is no such thing.

UV finishes are low in volatile organic compounds or low-VOC. UV finishes are low in volatile organic compounds or low-VOC. Infrared light combined with UV light and visible light reacts with the finish and slowly turns the finish darker or yellowish. Screening your hardwood floors finish and applying a fresh top coat is a great way to keeping your flooring looking like new. Use a UV inhibiting finish- Many manufacturers of polyurethanes also offer polys that have an UV inhibitor. In fact most pre-finished hardwood is made using this technology.

Read another article:

Source: pinterest.com

Source: pinterest.com

In fact most pre-finished hardwood is made using this technology. It also gives you durable abrasion- and chemical-resistant flooring. Radcoat UV Finish utilizes the same technology to immediately cure the finish on the job site in your home office or sport flooring. Technology that uses ultraviolet rays has been around for quite a while but only within the last decade has UV technology been put to use within the hardwood floor finishing process on a job site. French Oak Mystic 5 8 In Thick X 4 3 4 In Solid Hardwood Floors Hardwood Floors Solid Wood Flooring.

Source: pinterest.com

Source: pinterest.com

UV curing is quicker than any other curing process. So not only do they protect against early-use wear and tear they offer greater durability in the long-term which further prolongs the life of the wood floor. It also gives you durable abrasion- and chemical-resistant flooring. UV coating finishing system is a technology that integrated different type of UV coatings to provide a better surface protection for the hardwood flooring. Pin On Flooring.

Source: pinterest.com

Source: pinterest.com

Screening your hardwood floors finish and applying a fresh top coat is a great way to keeping your flooring looking like new. If your home has lots of natural light you may want to consider this option when refinishing your floors. Based on its formulation it is designed not only to protect its finish from fading but to protect even the woods color. Ultraviolet UV technology has been used for years by hardwood manufacturers to cure finishes in the factory. How To Choose Between Prefinished Or Site Finished Wood Floors Carlisle Wide Plank Floors Wood Floors Wide Plank Modern Wood Floors Wood Laminate Flooring.

Source: pinterest.com

Source: pinterest.com

Technology that uses ultraviolet rays has been around for quite a while but only within the last decade has UV technology been put to use within the hardwood floor finishing process on a job site. So not only do they protect against early-use wear and tear they offer greater durability in the long-term which further prolongs the life of the wood floor. It contains most of the essential features that make up for good wood protection. UV finishes typically are 20 to 40 percent more durable than conventional two-component finishes. How To Clean Oiled Uv Oiled Wood Floors Wood Floors Flooring Engineered Oak Flooring.

Source: pinterest.com

Source: pinterest.com

As a hardwood flooring manufacturer which also operated a UV cured finishing line the UV lamps in simulating sunlight enabled me to experiment with many UV protected finishes. UV blocking window films- Windows films are a great way to keep UV. It is a sharp delineation between covered and exposed wood. It contains most of the essential features that make up for good wood protection. Wood Interlocking Floor Tiles Solid Teak Wood Flooring Tile With Uv Protection Oiled Finish Snap Lock Interlocking Flooring Patio Flooring Outdoor Indoor Decor.

Source: pinterest.com

Source: pinterest.com

The finishes Skip to. Radcoat UV Finish utilizes the same technology to immediately cure the finish on the job site in your home office or sport flooring. KEY BENEFITS Appeals to consumers who select a wood floor based on its colour Useful for architects specifying wooden floors as part of an interior scheme Lengthens the time a natural wood floor keeps its original colour Can be used for all kinds of wood. UV blocking window films- Windows films are a great way to keep UV. Southwind Hard Surface Authentic Mix Variable Size Vinyl Plank In 2021 Vinyl Plank Waterproof Vinyl Plank Flooring Vinyl.

Source: pinterest.com

Source: pinterest.com

Screening your hardwood floors finish and applying a fresh top coat is a great way to keeping your flooring looking like new. The Benefits of UV Hardwood Floor Coatings. Use a UV inhibiting finish- Many manufacturers of polyurethanes also offer polys that have an UV inhibitor. UV coating finishing system is a technology that integrated different type of UV coatings to provide a better surface protection for the hardwood flooring. Hardwood Floor Oil Deks Olje D1 Owatrol Usa Hardwood Wood Oil Oils.

Source: pinterest.com

Source: pinterest.com

If you dont want the Walnut to. If you dont want the Walnut to. UV finishes typically are 20 to 40 percent more durable than conventional two-component finishes. When youre looking for something upscale and distinct consider the benefits of UV oil finish on hardwood floors of all types. Mwf 606 Rustic Oak Engineered Wood Flooring With Brushed Uv Oil Finish 150 X 15 X 1900mm See Our Website For P Engineered Wood Floors Flooring Wood Floors.

Source: pinterest.com

Source: pinterest.com

Now UV curing hardwood floors is really catching on. Thats why over a long period of time certain types of hardwood floors with oil based polyurethane finish turn that orangeyyellow color that no-one likes. Radcoat UV Finish utilizes the same technology to immediately cure the finish on the job site in your home office or sport flooring. In my experience there is no such thing. Boen Oak Antique Brown Handcrafted The Colour Pallet Of The Tree Is Different Which Is True For Bo White Oak Floors White Oak Flooring Bedroom White Oak Wood.

Source: ar.pinterest.com

Source: ar.pinterest.com

Unfortunately too the wood under the varnish eventually begins to deteriorate so that the adhesion between varnish and wood is reduced and you begin to see yellow patches that means it is time to strip it all off and start over. Technology that uses ultraviolet rays has been around for quite a while but only within the last decade has UV technology been put to use within the hardwood floor finishing process on a job site. UV curing is quicker than any other curing process. If you dont want the Walnut to. Urban Design Traditional Oiled Oak Engineered Parquet Engineered Wood Floors Engineered Parquet Flooring Engineered Parquet.

Source: pinterest.com

Source: pinterest.com

UV blocking window films- Windows films are a great way to keep UV. The best option add high UV index coatings to your next set of windows please contact the maker of the windows to ensure you can add. Based on its formulation it is designed not only to protect its finish from fading but to protect even the woods color. UV finishes are low in volatile organic compounds or low-VOC. Pin On Home.

Source: pinterest.com

Source: pinterest.com

It contains most of the essential features that make up for good wood protection. All wood reacts to sunlight. So if you are to get any UV protection for your wood at least it can be this one. Using ultraviolet light to cure a floor finish might sound futuristic but its a logical leap to take for contractors. 150mm X 600mm Brushed And Uv Lacquered Click Herringbone Engineered Oak Wood Flooring 14 3 2mm Thick Engineered Wood Floors Wood Floors Flooring.

Source: pinterest.com

Source: pinterest.com

It is a sharp delineation between covered and exposed wood. UV curing is quicker than any other curing process. Based on its formulation it is designed not only to protect its finish from fading but to protect even the woods color. It is a sharp delineation between covered and exposed wood. Pin On Materials Library.

Source: pinterest.com

Source: pinterest.com

Ultraviolet UV technology has been used for years by hardwood manufacturers to cure finishes in the factory. UV cured hardwood floors rival aluminum oxide pre-finished floors in terms of durability and lifespan. UV curing is quicker than any other curing process. So not only do they protect against early-use wear and tear they offer greater durability in the long-term which further prolongs the life of the wood floor. Boen Oak Andante White Castle Plank Collection European White Oak Engineered Hardwood Floors In A Uv Oil Fin Witte Eiken Vloeren Bevloering Hardhouten Vloer.

Source: pinterest.com

Source: pinterest.com

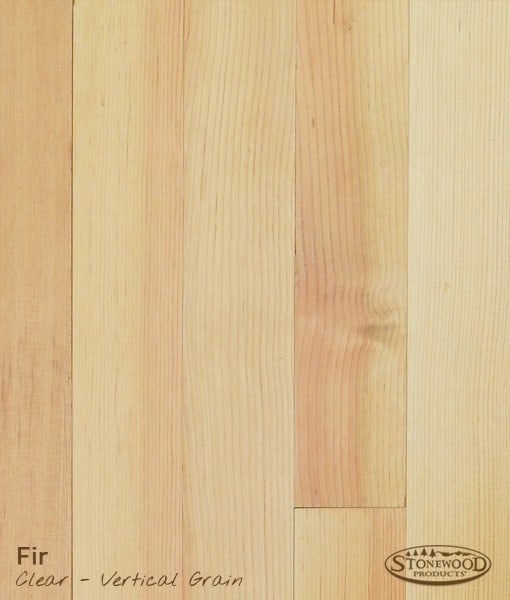

As a hardwood flooring manufacturer which also operated a UV cured finishing line the UV lamps in simulating sunlight enabled me to experiment with many UV protected finishes. So if you are to get any UV protection for your wood at least it can be this one. In fact most pre-finished hardwood is made using this technology. Your hardwood floors need a durable finish that maintains the visual appeal and natural comfort of wood. Pin On Texture Background.